One of the most common reasons for your sewing machine not stitching properly is that the bobbin has not been inserted correctly. It’s a sneaky problem because when threading your sewing machine, and inserting the bobbin, it can look correct even when it is not. Luckily it’s an easy problem to fix and I’m going to show you how to make sure your bobbin is alway inserted the correct way.

There are 2 ways that you can insert your bobbin into the casing of the sewing machine. This applies to both top loading bobbins and machines with a separate bobbin case. You can insert it the right way, or the wrong way!

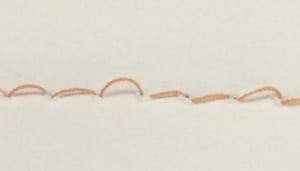

If you don’t know which is the correct way to put your bobbin in to the case then you have a 50/50 chance of getting the bobbin the right way round. Sometimes your machine sews a beautiful stitch and sometimes it doesn’t.

The information below relates to every sewing machine I have ever threaded in my almost 40 years of sewing. If your machine manual tells you differently for your particular model of machine, then you must use the manual instructions specific to your machine.